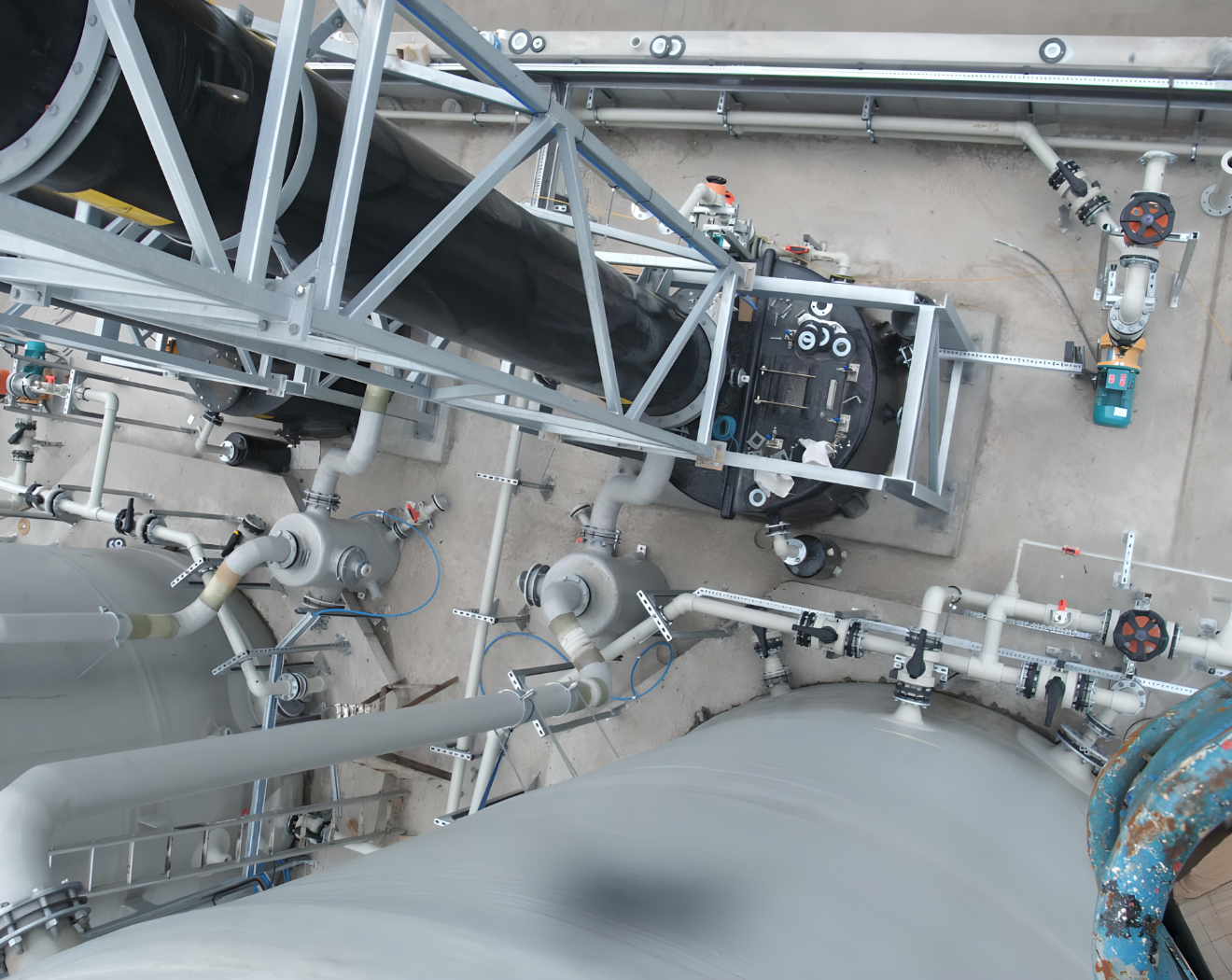

Tank Farm Installation for Augean PLC

BS EN 13121-3 Compliant Scrubber and Tank Refurbishment for Hazardous Waste Processing

ERG Hygrade was selected by leading hazardous waste specialist Augean PLC to deliver a major tank farm installation and scrubber refurbishment at one of its key processing facilities in the northeast of England.

Augean, known for its compliance-led solutions for complex liquid waste streams, required a combination of new-build infrastructure and reuse of existing equipment — demanding a flexible, fabrication-led approach. ERG Hygrade was responsible for the full design, manufacture and installation of all key equipment, delivered to BS EN 13121-3.

The project included fabrication and installation of a new ventilation scrubber and recirculation system, along with the refurbishment of an existing scrubber and three chemical storage tanks relocated from a decommissioned Augean site. ERG Hygrade also supplied and installed all interconnecting ductwork, discharge stacks, and double diaphragm pumps for waste liquor transfer.

End-to-End Delivery

To complete the system, ERG Hygrade provided new magdrive pumps for recirculation and waste liquor transfer, along with all interconnecting and process pipework, ensuring full functionality and long-term reliability of the site’s updated liquid handling and scrubbing systems.

This project demonstrates ERG Hygrade’s ability to manage complex refurbishment works, integrating both new and legacy assets into a fully operational and compliant installation — all delivered with a single point of responsibility.